Last Updated on August 1, 2020 by Amy

We took a break from the amazing train ride from Kandy to Ella and back to stop into Nuwara Eliya, a small town up in the mountains of Sri Lanka. This town is often called “Little England”, as the high society of the colony enjoyed the climate in Nuwara Eliya.

And here in Nuwara Eliya, it’s all about tea. Sri Lanka is the fourth-largest producer of tea in the world (behind China, India, and Kenya). Sri Lanka exports almost 350,000 tons of tea leaves a year. While the first plantation was in Kandy, Nuwara Eliya has become the hub for all things tea.

You should know: we packed fleeces on our trip, specifically for Nuwara Eliya, and I wore my fleece all day here.

Victoria Gardens

After breakfast, we enjoyed a morning stroll around the Victoria Gardens. For a small fee (300 LKR per foreigner), you gain entry to this small park. Even though it’s early in the year and a bit chilly, there were plenty of flowers to look at around the gardens.

Pedro Tea Plantation

We hired a tuk-tuk to take us to the Pedro Tea Plantation. We arrived a bit early for the tour so we had some time to wander around the tea fields. Then, we donned an apron and hair net to take the tour inside the working tea factory. No photographs were allowed, unfortunately, so you’ll just have to imagine.

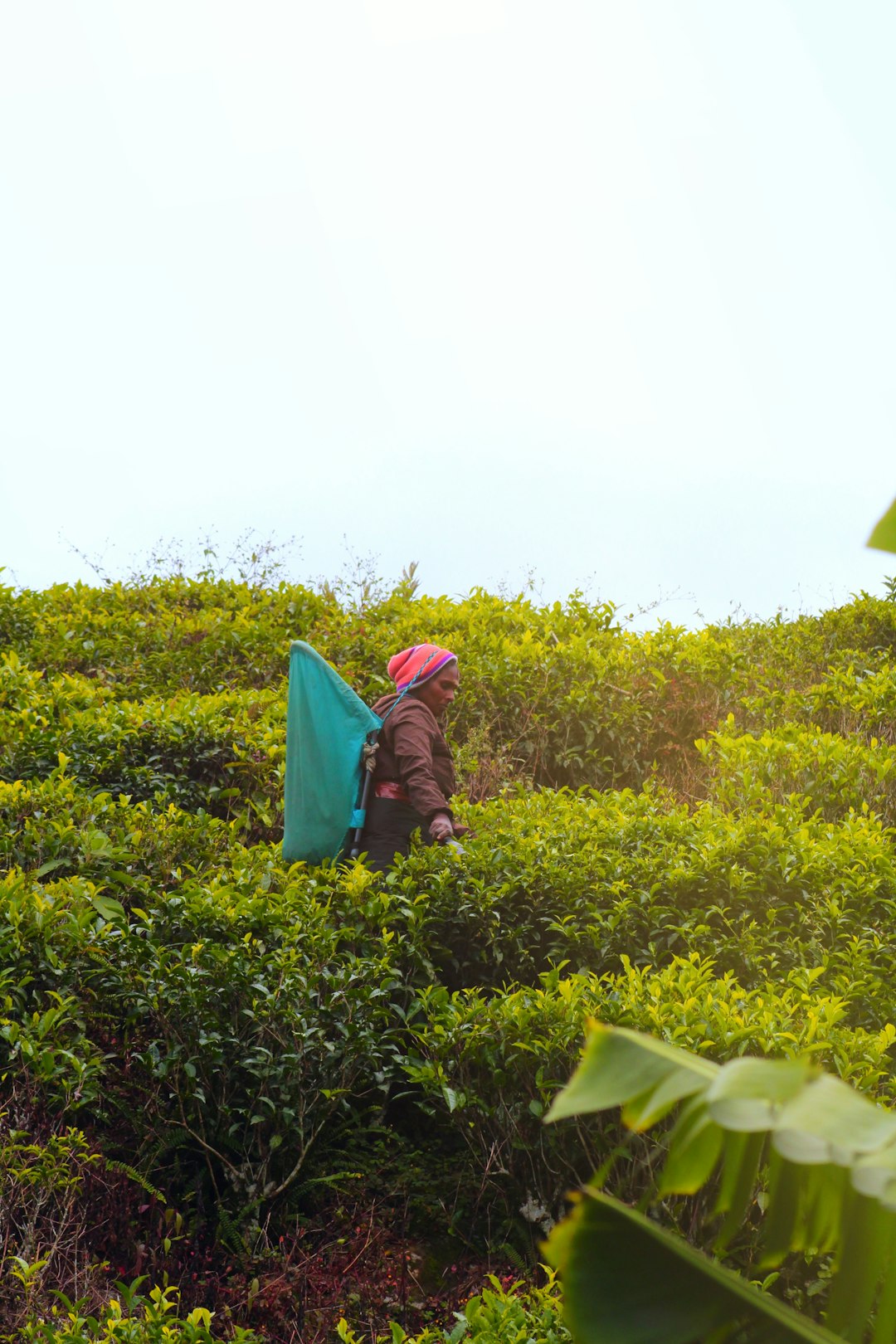

We started at the scale, where the tea pickers bring their harvest in. The tea leaves are picked every six days. The tea pickers only pick the young, green leaves, so you can identify which fields need picking because the tips of the bushes are lighter in color. Tea pickers work eight hour days, and every two hours they bring their collection in to weigh. On a good day, the scale weighs 15 to18 tons of tea leaves.

Next, the factory staff lays out the leaves and dries the leaves with big blowers. The warm air from the blowers removes about forty-five percent of the moisture, and the leaves become limp and pliable. Then, the leaves are rolled in a machine that presses and rotates, literally twisting the leaves around. It smells green and heavenly.

Machines separate the leaf segments, and bigger pieces go back into the rollers. Smaller pieces are dried in an oven for 21 minutes. A special machine removes the twigs, which the factory uses for fertilizer. Then the tea leaves are separated by grade, and the grade is what determines the type of tea.